Dixon - Introduction

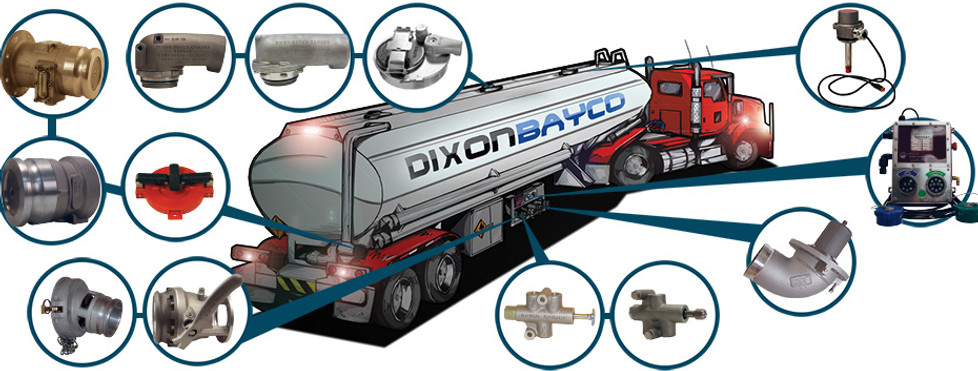

The Dixon Valve & Coupling group that we know today have a wide range of innovative and high quality fluid related equipment for the petroleum & chemical industries.

The company was originally established in 1916 by Howard W. Goodall with the goal of designing & manufacturing the very best industrial valve & rubber hose couplings. The very first product that Dixon patented was the Rotary Hose Coupling in 1917 which over the years has developed further but the basic concept is still used today in high pressure oil drilling.

After more than 100 years, it is not surprising to find that Dixon products are found on every continent around the world and they continue to innovate and excel in their markets.

Dixon - API Automatic Coupler

Dixon's API automatic coupler has a locking 5 cam design resulting in easy alignment and tight connection when connecting to API adaptors on road tankers.

Competitively priced together with a 5 year mechanical warrantee, it is the best value for money API coupler on the market.

Fully compliant with API RP1004:2003 standards.

Normal wear & tear items (including seals) not covered under warrantee

Chemical compatibility FKM-B seals: (fitted standard)

-

Petrol

-

Diesel

-

Jet fuel / JetA1

-

Avgas

-

100% Ethanol

-

100% Methanol

-

100% Biodiesel

-

Any blend of the above fuels

-

Crude Oil

The Dixon API automatic coupler is a great choice for your loading terminal in relation to long term safe & reliable operation.

Dixon - Flotech Overfill Protection Equipment

Standard 5 Wire and Plug & Play 2 Wire Sensors

Manufactured to EN13922 with 5 year Warranty

-

Aluminium 2 or 5 wire

-

Stainless steel 2 or 5 wire

-

Plug & Play wiring

Checkmate On-Board Controller

Can be setup to accommodate a variety of configurations both 2 or 5 wire overfill sensors, as well as bottom retain sensors. Waterproof to a depth of 3m and also complete with a 5 year warrantee.

TIM - Trailer Identification Module

Each of Dixon's FloTech Trailer Identification Modules contain a globally unique identification number used to positively identify the specific tanker.

The internal computer chip for these modules is independently manufactured by a third party in the USA for both Dixon & Scully, therefore between the two major brands there can be no duplication of the globally unique identification numbers.

The unit is mounted within the overfill prevention socket housing on the trailer.

Dixon's module is compatible with and communicates with the Vehicle Identification Prover (VIP) or rack control system.

Dixon - Bayloc Dry Disconnects

Dixon's Bayloc Dry Disconnects are well known for their reliability, build quality and overall safety value they add when transferring hazardous and potentially life threatening chemical / acid products.

Fully compatible with all other cam and groove style dry disconnects ie. OPW Kamvalok.